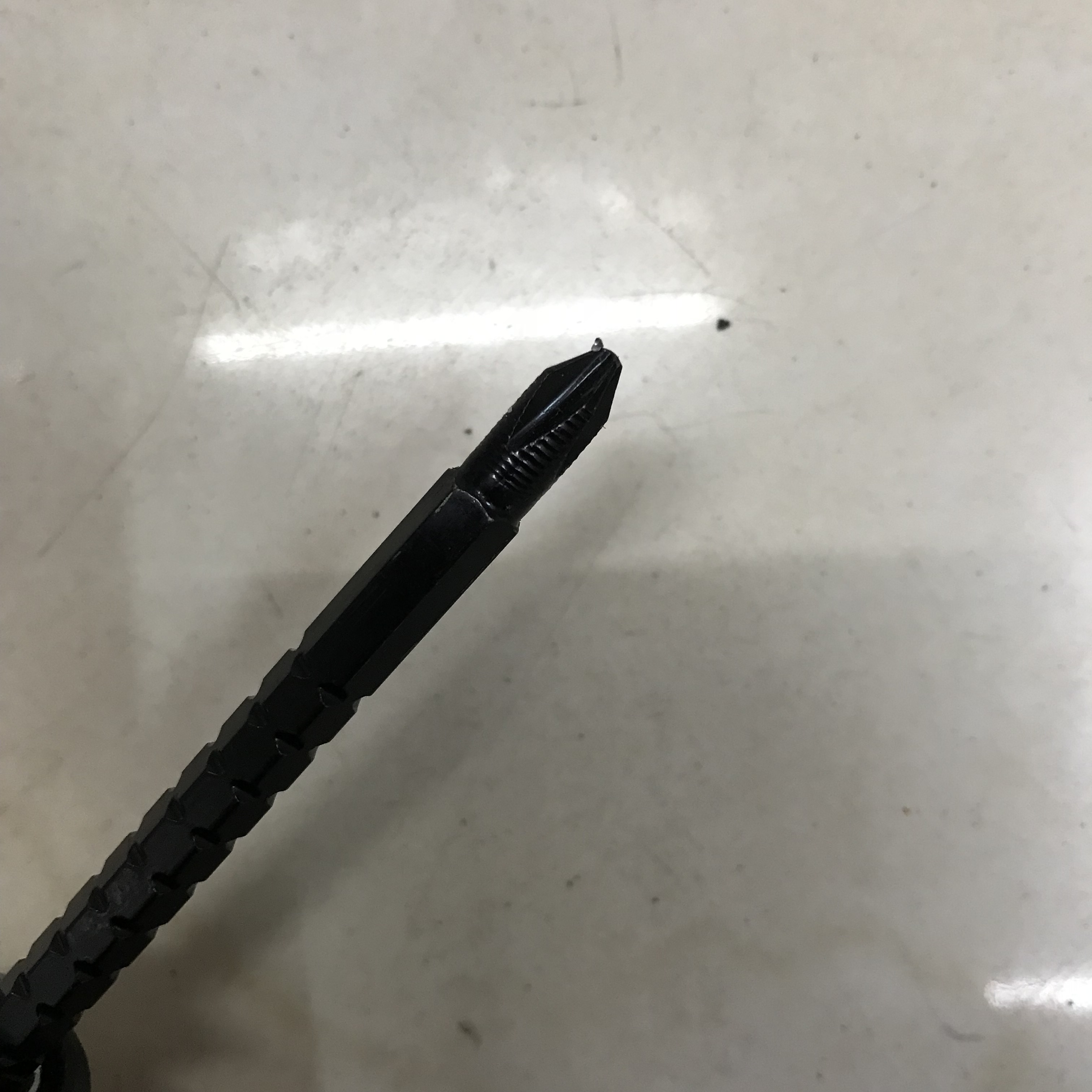

In daily work, a reliable tool can greatly improve efficiency and reduce fatigue. Today we are going to introduce a sharp tool specially designed for high-intensity tasks- industrial-grade handle line screwdriver .

First look at its core features: Ruggedness, precise control and user-friendly design concept together constitute the outstanding competitiveness of this product. It is made of high-quality materials to ensure that it can still maintain its original state after long-term use; at the same time, precision machining ensures that each rotation can achieve the desired effect.

Why is ergonomic design important?

Many people may overlook the importance of this, but a good screwdriver should make it easy to hold and will not cause the accumulation of hand pressure. The screwdriver pays special attention to this, taking into account the user's needs during the development process and incorporating this feedback into the final version.

By optimizing the handle shape and surface texture treatment, comfort can be maintained even under continuous operation for several hours. This is not only responsible for health performance, but also improve the overall work efficiency.

Selection criteria for screwdrivers in high-intensity working environments

When you are faced with complex and changing working conditions, the right choice becomes especially important. Industrial grade means that it can handle extreme situations without showing signs of failure or damage.

From impact resistance to anti-slip performance to the application of anti-corrosion protection layer, it has been comprehensively upgraded, so that it can still perform well in harsh environments.

From electronic assembly to mechanical maintenance: full interpretation of applicable scenarios

Whether you are a technician engaged in the assembly of fine electronic products or a professional technician who needs regular maintenance of large equipment, this screwdriver can meet your requirements.

For the former, the small and flexible features allow it to be accurately inserted into a small space for operation; for the latter, it relies on its strong torque output to remove the fastening parts.

Comparative test: the difference between ordinary screwdriver and industrial-grade model

In order to better understand the differences between the two, we conducted a detailed comparative experiment. The results show that after completing the same amount of tasks under the same conditions:

- -Industrial-grade products are significantly less labor-saving and less time-consuming;

- -It will not feel sore and uncomfortable when held for a long time.

In addition, it was also found that the service life has been extended many times due to structural improvements! These are the advantages that ordinary household types cannot match.

The secret weapon to improve work efficiency-details determine success or failure

In addition to the main advantages mentioned above, there are some small places that are easily overlooked that are also commendable. For example, the replaceable cutter head design allows users to freely switch different types of sizes according to the actual situation without carrying too many spare supplies; there is also the self-contained lighting function to facilitate the precise operation in the dark area, etc.... Every insignificant but indispensable part is silently contributing its own value.

How to properly maintain and extend the service life of the screwdriver

finally, don't forget to take daily care measures ~ simple cleaning and wiping can not only prevent dust particles from eroding the metal surface, but also find hidden dangers in time and solve them in advance so as not to affect the subsequent normal use experience.

Take care of your favorite things according to the above methods. I believe it will accompany you through the long journey of years!