Discover the secret of ruggedness: the choice of industrial-grade materials

The key to the L-shaped handle wire screwdriver's excellent performance in harsh environments is the selection of top industrial grade materials. From corrosion-resistant metal parts to non-slip and wear-resistant handle design, every detail is the result of careful selection. These high-quality materials can not only withstand changes in high temperature, low temperature and humidity, but also resist chemical erosion to ensure long-term stable use. Especially in a high-load working environment, reliable materials are the cornerstone of safety and efficiency.

The choice of such high-end materials is not accidental, but an inevitable decision after an in-depth understanding of user needs. Whether it is frequent knocks on the construction site or day-to-day operations on the factory assembly line, this screwdriver can easily handle without being damaged. This means higher cost performance and lower maintenance costs, saving a lot of time and money for enterprises and individual users.

The key to precise operation: unique cutting edge technology and ergonomic design

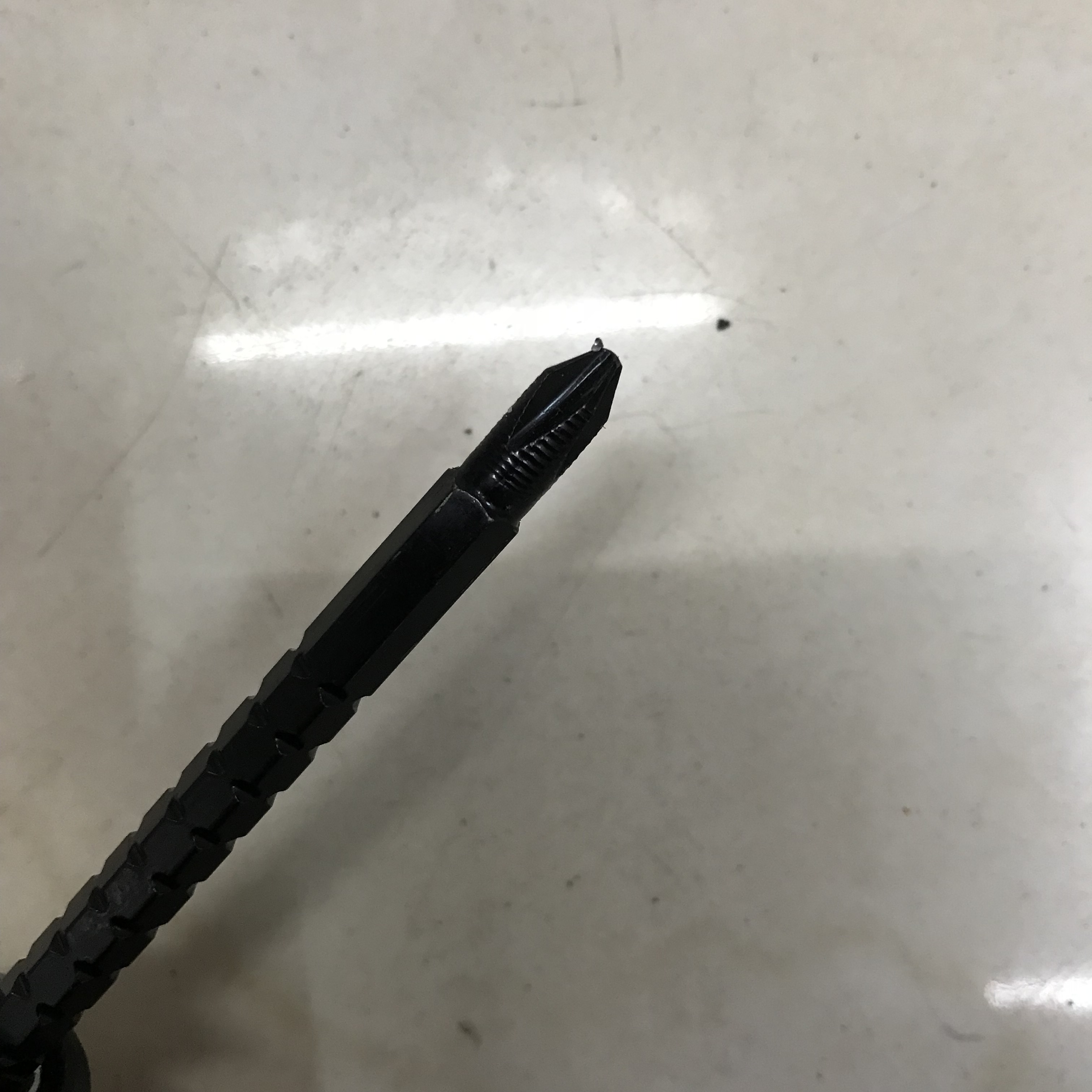

To achieve the perfect fastening operation, can not be separated from the fine grinding of the cutting edge process. This screwdriver uses a special cutting technology, so that its tip is sharp and has good anti-wear characteristics. This design allows it to be accurately embedded in the screw hole in the smallest space, and will not easily slip or damage the surface. In addition, the cutting edge can adapt to different types and sizes of screw heads after precision adjustment, which greatly improves compatibility and flexibility.

At the same time, considering the comfort of long-term use, the designers also paid special attention to the ergonomic considerations of the handle part. The soft and tough rubber wrap provides enough friction to prevent accidental detachment, while also having a cushioning effect to reduce arm fatigue. The overall shape is smooth and easy to grasp, and can apply appropriate pressure to complete the task at any angle. Compared with other common products of the same type on the market, our screwdrivers are undoubtedly more user-friendly and practical.

All-in-one: an ideal solution for multiple industries

Whether it is laying electrical lines at the construction site of a busy urban transportation network, or being responsible for the assembly and debugging of precision instruments in a modern production workshop; or facing a sudden failure of outdoor power facilities that requires emergency repairs... L-type handle wire screwdriver can always find its place of use. With its compact and flexible body structure and excellent torque output capability, it can do almost all daily repair and maintenance work.

In fact, many companies and organizations have chosen our screwdriver as one of the tools of choice. An engineer who has been engaged in the automobile manufacturing industry for many years said: "Since the use of this screwdriver, the work efficiency has been significantly improved by at least 30%!" Another electrician also said with praise: "I don't worry about encountering difficult small screws anymore. I can complete the task smoothly every time." It can be seen that this small screwdriver carries countless successful moments behind it.

Efficiency Helper: Convenient design details cannot be ignored

In order to give users a better experience, this screwdriver is also cleverly conceived in many subtleties. For example, the magnetic head can firmly adsorb small accessories, thus avoiding the delay of construction period caused by falling. In addition, the design of the replaceable batch head solves the conversion problem between different specifications and models, and truly achieves multiple functions in one machine.

In addition, the screwdriver is also equipped with a torque adjustment device with clear scale identification, which is convenient to adjust the appropriate strength according to the actual situation, which can ensure the firmness and prevent damage caused by excessive tightening. Although such functional improvements may seem insignificant, they are a real help to front-line staff. They not only simplify the construction process and reduce the probability of error, but also significantly reduce the discomfort caused by physical exertion.

Behind Quality Assurance: Strict Production Standards and Testing Processes

Behind every excellent tool is a complete quality management system. In order to ensure that every factory L-shaped handle line screwdriver can meet the expected requirements, the manufacturer has established extremely stringent standards for full monitoring and management. From the initial selection of raw materials, the qualification of suppliers will be strictly screened until the final round of finished products pass the sampling inspection before they can be put into storage and shipped.

especially according to the demand characteristics of specific industries, a series of professional test items specially designed to evaluate performance indicators have been customized, such as stability test under simulated extreme temperature environment, statistics of repeated bending and breaking times, high voltage current impact test, etc. Only through layers of tests can we truly win the recognition and trust of the market. Therefore, when we pick up this screwdriver, it is like holding a heavy responsibility commitment-this is the best witness of brand strength.

Future Trend Outlook: Intelligent Technology Enabling Traditional Hand Tools

As the pace of technological progress is accelerating, the future of industrial-grade screwdrivers may usher in unprecedented opportunities for change. Imagine that if an ordinary screwdriver is integrated with a miniature sensor, it can monitor its own operation in real time and transmit data to a smartphone application through a Bluetooth connection, allowing users to keep abreast of the latest developments and make corresponding adjustments in time. For example, the use of new nano-coating technology to further strengthen the level of anti-corrosion protection, so that the life of the tool to get a qualitative leap.

Of course, all these beautiful ideas will take time to gradually become reality.