Industrial environments have evolved dramatically over the years. As machines become more complex and production demands rise, the tools professionals rely on must keep pace. In this landscape, the L-Handle Line Screwdriver has emerged not just as another option, but as a necessity for those who demand precision, durability, and performance under pressure.

When Traditional Tools No Longer Suffice: The New Challenges of Industrial Workplaces

Conventional screwdrivers—whether flathead or Phillips—often fall short in today’s high-stakes industrial settings. Their limitations become apparent when dealing with high-torque applications, confined spaces, or repetitive tasks that strain the wrist and forearm. The L-Handle Line Screwdriver, with its unique geometry, addresses these pain points directly, offering a modern solution for modern problems.

The Secret Behind the L-Handle: Design Meets Engineering

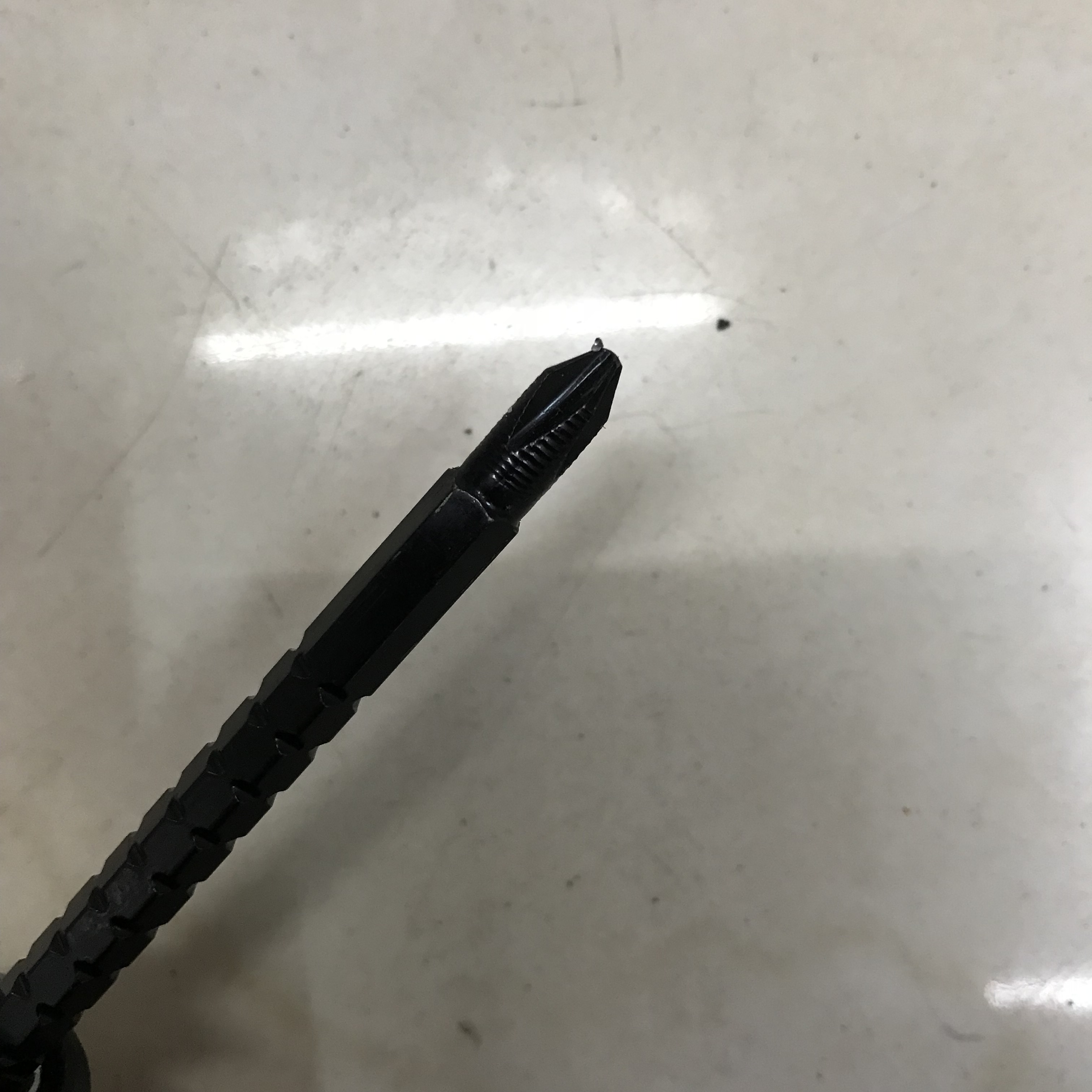

At first glance, the L-Handle may seem like a simple twist on traditional designs, but beneath its sleek exterior lies a carefully engineered tool that maximizes efficiency and comfort. The 90-degree bend in the handle allows users to apply force in a straight line, reducing wrist fatigue and increasing torque. This design also makes it easier to work in tight corners where a straight screwdriver would be nearly impossible to use effectively.

The materials used in construction are equally important. Crafted from industrial-grade chrome-molybdenum steel, these screwdrivers resist wear and maintain edge integrity even after thousands of uses. The anti-slip handle ensures a secure grip, even in oily or wet conditions, making it a reliable companion in any industrial toolkit.

Real-World Power: What Engineers Say

We spoke with professionals across multiple industries—electrical engineering, mechanical maintenance, and construction—to understand how the L-Handle Line Screwdriver performs in real-life scenarios. From tightening control panel screws in a power plant to assembling heavy machinery on a factory floor, the feedback was consistent: this tool makes a noticeable difference.

One mechanical engineer shared how the L-Handle allowed him to complete equipment repairs faster and with less physical strain. Another technician in the construction field praised its ability to access hard-to-reach fasteners without damaging surrounding surfaces. These testimonials highlight not just the utility of the tool, but its impact on daily productivity and comfort.

Putting It to the Test: L-Handle vs. T-Handle vs. Straight Screwdrivers

To truly understand the value of the L-Handle, we conducted a series of comparative tests across three popular screwdriver types: L-Handle, T-Handle, and straight models. The results were telling. In high-torque applications, the L-Handle outperformed the others in both output and user fatigue. In tight spaces, its angled design made it the only viable option. And for extended use, the ergonomic benefits of the L-Handle were undeniable.

Whether in the lab or on the shop floor, professionals found themselves reaching for the L-Handle more often than not. It’s not just a tool—it’s a trusted partner in the field.

More Than a Tool: A Commitment to Safety and Precision

In industrial environments, safety is paramount. A tool that slips or fails at a critical moment can lead to costly downtime or even injury. The L-Handle Line Screwdriver is designed to minimize these risks. Its secure grip and precise tip reduce the chance of cam-out or slippage, ensuring that each fastener is tightened or loosened exactly as intended. This reliability translates to safer working conditions and fewer errors in high-pressure situations.

The Hidden Workhorse: Why It Belongs in Every Professional Toolbox

Despite its understated appearance, the L-Handle Line Screwdriver is a workhorse in the industrial world. It's used daily in critical applications—from electrical panel maintenance to assembly line operations. Its versatility and performance make it indispensable, and its presence in professional kits is growing rapidly.

Many technicians have come to rely on it not just for occasional tasks, but as a go-to tool for precision work. It’s not flashy, but it gets the job done, every time.

Long-Term Value: A Smart Investment for Any Workshop

While cheaper alternatives may seem cost-effective at first, they often wear out quickly, requiring frequent replacements and disrupting workflow. The L-Handle Line Screwdriver, built to last, represents a long-term investment that pays dividends in durability, performance, and reduced downtime. When you factor in the cost of replacing inferior tools and the labor lost due to inefficiency, the economic advantage of choosing a high-quality L-Handle becomes clear.

Looking Ahead: Tools for the Age of Industry 4.0

As industries shift toward automation and precision manufacturing, the tools we use must evolve as well. The L-Handle Line Screwdriver is already finding its place in semi-automated assembly lines and smart factories, where consistency and reliability are non-negotiable. Future iterations may include modular designs, integrated torque sensors, or even compatibility with digital tool tracking systems—proving that even the most traditional tools can adapt to the future.

For industrial professionals, the L-Handle Line Screwdriver is more than just another tool in the box—it's a symbol of quality, innovation, and dependability. Whether you're working in a power plant, on a construction site, or in a high-tech manufacturing facility, this screwdriver is ready to meet the demands of today and tomorrow.