There’s a quiet moment most professionals know all too well—the twist that slips, the handle that cracks under pressure, or the bolt that refuses to budge no matter how hard you push. In high-stakes environments where every second counts, an ordinary screwdriver isn’t just inconvenient; it’s a liability.

When the Screwdriver Becomes an Extension of Your Hand: Redefining Precision in Hand Tools

Imagine tightening a terminal block in a live electrical panel, only for your screwdriver to cam out and spark dangerously close to your fingers. Or picture yourself beneath a vehicle chassis, straining to apply enough torque through a cramped angle. These aren’t hypotheticals—they’re daily frustrations faced by technicians, electricians, and mechanics worldwide.

The L-handle design transforms this experience. By aligning force directly along the axis of the screw, it leverages natural wrist alignment and mechanical advantage unlike traditional straight or T-handled drivers. The result? Greater control, reduced fatigue, and a level of precision that feels intuitive—like the tool is part of your own anatomy.

The Engineering Philosophy Hidden in Metal: Inside a True Industrial-Grade L-Handle Screwdriver

Beneath its simple silhouette lies a symphony of material science and mechanical intelligence. At the core is a shaft forged from chromium-vanadium steel—an alloy renowned for its resilience under repeated stress and resistance to torsional deformation. This isn’t merely strong metal; it’s fatigue-resistant, heat-treated steel capable of enduring thousands of cycles without yielding.

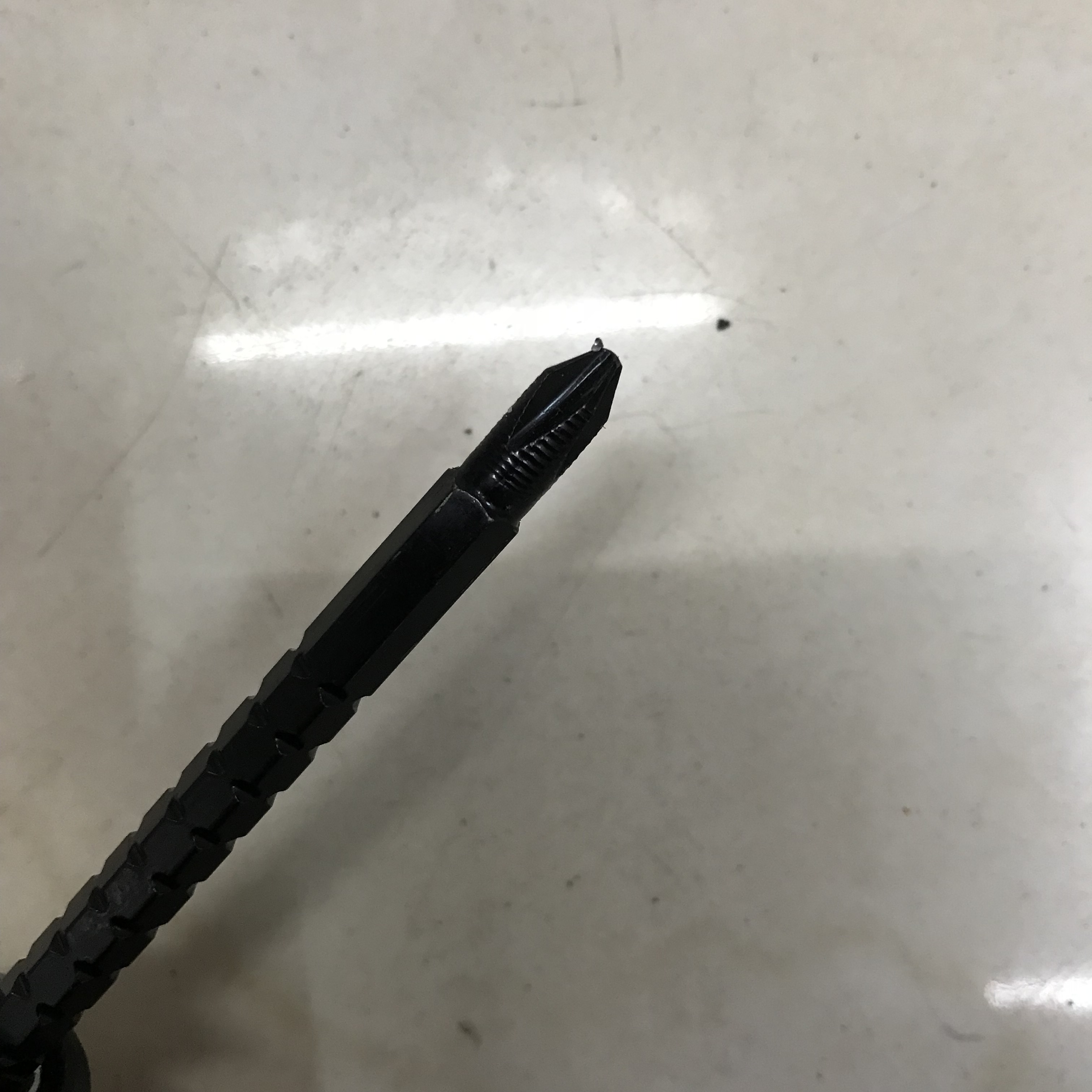

The L-shaped handle isn't just about form—it's a calculated balance between leverage and compactness. Its geometry converts downward palm pressure into rotational torque with remarkable efficiency, reducing strain on tendons and joints. Meanwhile, the tip undergoes micron-level grinding to maintain tolerances within 0.1mm, ensuring clean engagement even in worn or recessed screws.

More Than a Tool—A Symbol of Professional Identity

For an electrician working a midnight outage, the reliability of their tools means safety and speed. The L-Handle Line Screwdriver has become a trusted companion in switchgear rooms and overhead trays, where one slip could mean downtime—or worse. Its slim profile allows access behind panels where power density leaves no room for error.

Automotive technicians praise it as a “third hand” in engine bays packed with sensors and shielding. Whether loosening a stubborn sensor bolt or adjusting delicate throttle linkages, the driver delivers consistent feedback and unshakable grip. Even DIY enthusiasts find themselves upgrading from basic kits once they experience the confidence this tool provides—from assembling custom PC cases to restoring vintage furniture with fragile threads.

Surviving the Harshest Conditions: Moisture, Height, and Vibration

This screwdriver doesn’t retreat when conditions turn hostile. A dual-layer anti-corrosion coating resists salt spray and chemical exposure, tested rigorously in simulated coastal and industrial environments. Field reports show zero pitting after 500 hours of continuous salt mist exposure—a benchmark few hand tools achieve.

Even with sweaty palms or vibrating machinery nearby, the knurled grip and optimized center of gravity prevent slippage. Textured zones match natural finger placement, while weight distribution keeps the tool stable during prolonged use. It performs equally well in sub-zero freezers and near furnace decks, thanks to materials validated from -40°C to 120°C.

The Art of Torque: Balancing Power and Control

Unlike powered drills that often over-torque small fasteners, the L-handle empowers users with granular control. You can start with feather-light turns for sensitive components, then gradually ramp up force using body weight—not wrist snap. This transition from finesse to strength minimizes cam-out and thread damage.

User trials tracking 200 consecutive drive cycles showed less than 2% decline in torque consistency. No wobble. No deformation. Just steady, predictable performance. Compared to standard cross-head screwdrivers, testers reported up to 40% reduction in wrist discomfort during extended operations.

Why Professionals Are Returning to the Basics

In an era dominated by cordless impact drivers and smart tools, there’s a growing movement back toward refined manual instruments. Why? Because simplicity breeds reliability. When batteries die or electronics fail, the L-Handle Line Screwdriver still works—flawlessly.

Every saved minute avoiding tool failure adds up. On complex jobsites, having one utterly dependable tool reduces cognitive load and increases workflow continuity. In emergencies, it becomes the anchor—the “go-to” instrument professionals reach for instinctively.

A Legacy Forged in Steel: From Factory Floor to Family Heirloom

Some tools are used. Others are remembered. We’ve heard stories of fathers passing down their original L-handle drivers to apprentices—and now, to their children. One user shared a photo of his father’s screwdriver, its chrome shaft dulled but still functional after 35 years of service.

This longevity is no accident. Modular construction allows tip replacement and handle refurbishment, extending life far beyond disposable alternatives. More than hardware, these tools become vessels of skill transfer—silent witnesses to projects completed, problems solved, and knowledge passed hand to hand.

The L-Handle Line Screwdriver isn’t designed to impress with flashy features. It’s built to disappear into your workflow—only revealing its worth when everything else fails. That’s the mark of true industrial excellence: not noise, but endurance. Not novelty, but necessity.