There’s a moment, deep inside a wind turbine nacelle or beneath the deck plates of a cargo vessel, when every ounce of leverage counts. The air is thick with oil mist and tension. A seized M12 bolt refuses to budge. Fingers cramp around a slipping handle. This is where ordinary tools fail — and where the L-Handle Line Screwdriver begins to prove its worth.

When Power Meets Precision: An Engineering Breakthrough in Grip Design

In high-torque environments, standard screwdrivers don’t just underperform — they become liabilities. Twisting metal, fatigued wrists, dropped tools in critical zones — these aren’t inconveniences; they’re productivity killers. The L-Handle design isn’t merely aesthetic; it’s a calculated response to physics itself. By aligning force along a straight line from hand to tip, it eliminates lateral stress that plagues traditional T-handles or inline drivers.

Imagine applying steady, unwavering pressure in a confined engine bay, your arm braced against steel framing. With one smooth motion, the stubborn fastener releases. No jerking. No slippage. Just controlled, linear torque — exactly as intended.

The Sound That Rose Above the Workshop Noise: A Conversation with Carlos Mendez, Lead Maintenance Supervisor

"We used to go through three screwdrivers per shift on the hydraulic assembly line," says Carlos, wiping grease from his forearm. "Not because the bolts were too tight — but because the tools wouldn’t hold up. My guys came to me with wrist pain, calluses, even minor tendonitis."

After switching to the L-Handle Line Screwdriver six months ago, downtime dropped by 40%. “It’s not magic,” he adds. “It’s mechanics. The way the force travels straight down the shaft? You feel it — less vibration, no twisting in your palm. Now we finish jobs faster, and nobody’s complaining about sore hands.”

Steel Bones, Craftsman’s Soul: The Philosophy Behind Every Component

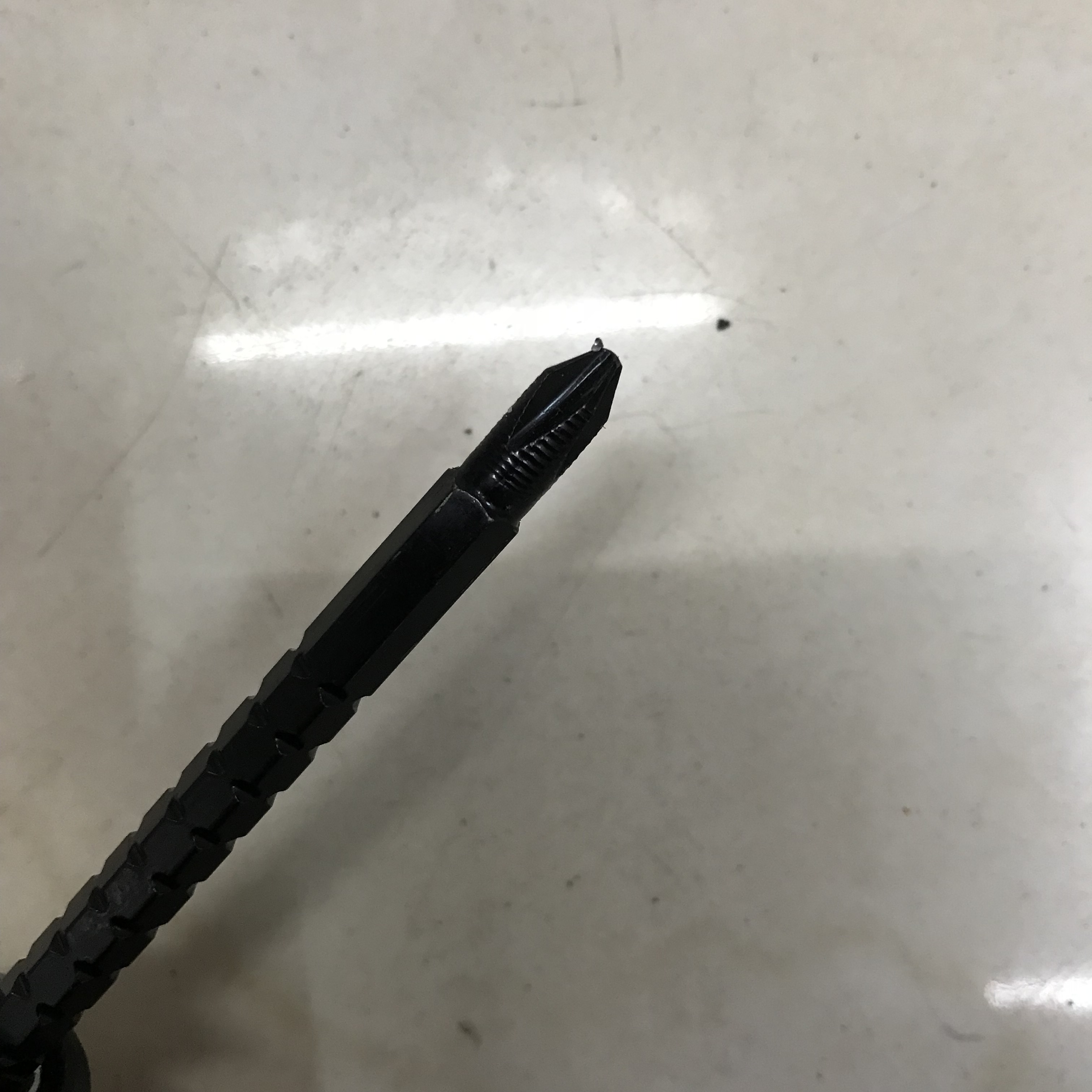

This isn’t assembled — it’s forged into purpose. The tip is crafted from hardened S2 high-carbon steel, heat-treated to resist cam-out and wear, even after thousands of cycles. It bites cleanly into recessed heads without rounding corners — crucial when replacement parts are miles away.

The handle, made from impact-resistant thermoplastic elastomer, doesn’t just cushion; it grips. Textured grooves conform to gloved fingers, maintaining control in wet or oily conditions. Most importantly, the entire unit is forged as a single piece — no screws, no joints, no weak points. Drop tests show it survives repeated impacts from 3 meters onto concrete. Compare that to conventional models with hollow handles or glued joints — many crack under half the stress.

More Than a Fastener Driver: Unconventional Uses Across Industries

On offshore platforms, technicians rely on its balanced weight distribution during高空作业 — the centered mass reduces swing risks and accidental drops. In automated production lines, engineers repurpose it as a manual override lever for jammed conveyors. Wind farm crews have been known to use it as a makeshift alignment gauge due to its perfectly straight shaft and repeatable depth markings.

Its versatility stems from reliability. When you know a tool won’t bend, break, or slip, you start trusting it beyond its original function.

Color as Function: Why Orange and Black Isn’t Just a Choice

The bold orange handle isn't for branding flair — it's a safety imperative. In dimly lit plants or cluttered workbenches, high-visibility colors reduce search time and prevent loss. Studies show workers locate bright tools up to 70% faster than dark ones. Combined with deep anti-slip texturing validated through ergonomic grip trials, this handle maintains secure contact even with sweaty or gloved hands.

And whether deployed in Arctic rigging stations at -30°C or near furnace-fed machinery at 60°C, the polymer retains flexibility and adhesion — no cracking, no hardening, no compromise.

The Silent Testimonials: What Worn Edges Reveal

A photograph of a blade edge caked in grime, yet still holding a razor-sharp corner. A close-up of a technician’s gloved hand rotating the tool one-handed while suspended in a harness. The faded spot in a toolbox where this driver is always pulled first — these aren’t staged shots. They’re evidence. Tools don’t earn loyalty through marketing; they earn it through survival.

When Standard Is Just the Starting Point

To meet ISO industrial durability standards, our team subjected prototypes to over 10,000 cyclic torque applications — far beyond typical usage. One early version failed at the neck junction. Instead of reinforcing with welds, we redesigned the taper geometry entirely, allowing stress to dissipate smoothly across the transition zone. That failure became the blueprint for strength.

We didn’t build this to pass certification — we built it to redefine what certification should require.

Will There Be Tools That Last Generations?

In an age of disposable gear, the L-Handle Line Screwdriver stands apart — not only because its replaceable tips extend service life, but because it challenges the idea that tools must be replaced rather than maintained. Some day, perhaps, a young technician will open their case to find a well-worn L-handle passed down by a mentor. No digital manual. No battery. Just honest craftsmanship, ready to turn another bolt.

Because real precision isn’t measured in millimeters alone — it’s measured in trust, transfer, and time.