L-Handle Line Screwdriver – Durable Industrial-Grade Tool for Precision & Performance

It was 3 a.m. on a bustling automotive assembly line when everything came to a halt. A single torque-sensitive bolt had slipped under the pressure of a standard screwdriver, throwing off calibration and delaying the entire shift. The technician wiped sweat from his brow—not from heat, but from strain. His wrist ached, his grip faltered, and the tool he trusted failed him at the worst moment. That’s when the L-Handle Line Screwdriver stepped in—not just as a replacement, but as a revolution in hand tool performance.

In environments where precision meets relentless demand, every rotation counts. This isn’t just about tightening screws; it’s about maintaining momentum, ensuring safety, and delivering flawless results—shift after shift. The L-Handle Line Screwdriver isn’t merely another addition to your toolkit. It’s the silent partner that transforms fatigue into focus, and uncertainty into unwavering control.

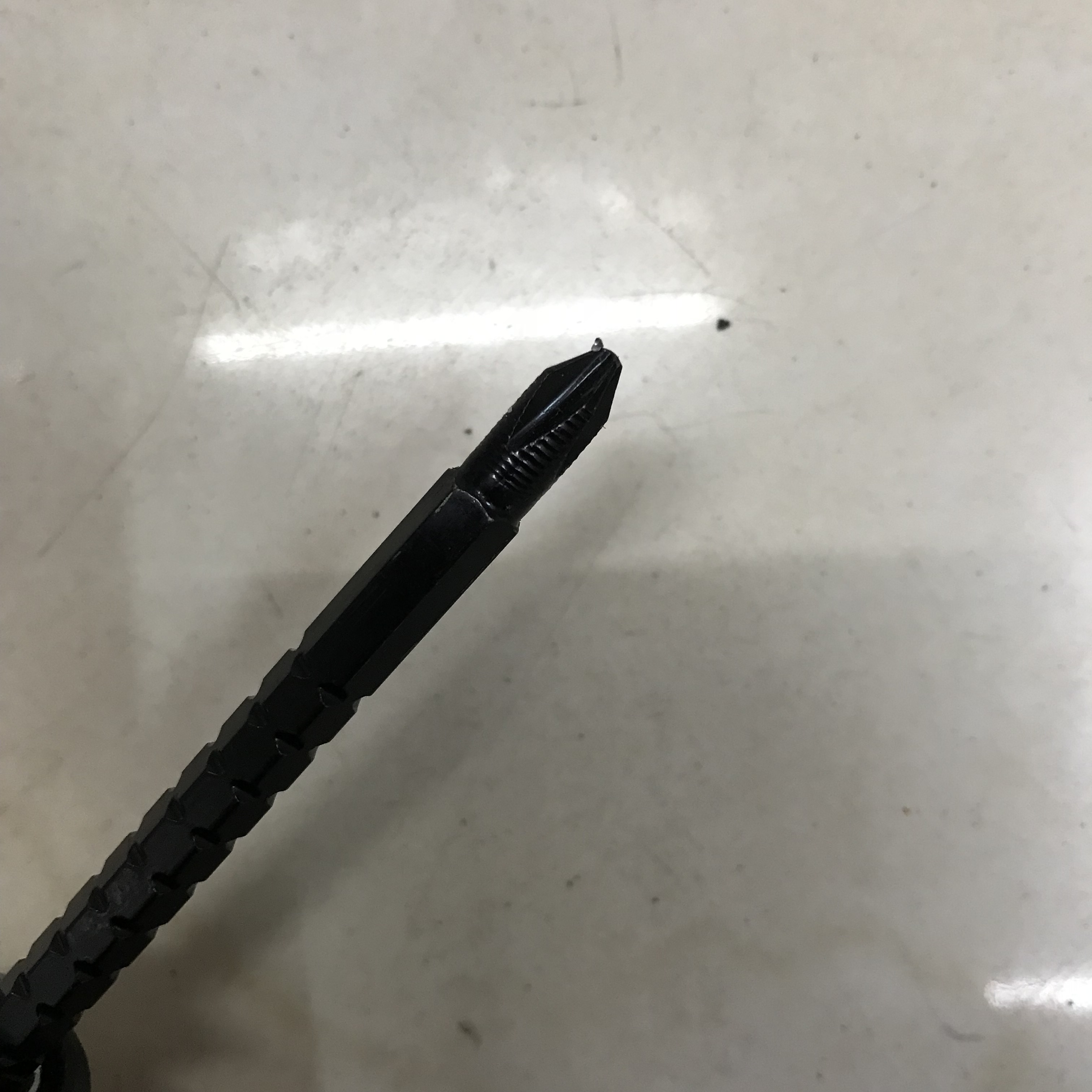

Gone are the days when “industrial-grade” simply meant thicker metal or a tougher coating. Today’s professionals need more than brute strength—they need intelligence built into every curve and contour. Unlike consumer-grade screwdrivers that buckle under repetition, the L-Handle Line Screwdriver is forged from high-tensile alloy steel with a hardened core, resisting deformation even after thousands of cycles. Its anti-slip grooves aren’t etched—they’re machined directly into the shaft, ensuring consistent torque transmission without slippage.

Beneath the surface lies a rigor most tools never face: tested against twisting forces exceeding 25 Nm, exposed to corrosive agents, and cycled through extreme temperature gradients. Each unit undergoes 13 stringent quality checkpoints before leaving the facility—not because standards demand it, but because real-world consequences depend on it.

The brilliance of the L-Handle design isn’t immediately obvious until you use it. At first glance, it appears deceptively simple—a straight bar bent at a right angle. But within that geometry lies a masterclass in mechanical advantage. By aligning your arm, wrist, and tool in a single plane, the L-shape converts rotational effort into direct linear force. No awkward wrist cranking. No loss of alignment. Just pure, unbroken energy transfer from palm to tip.

Imagine working inside the cramped chassis of a turbine engine, where angles are tight and visibility is low. With a conventional screwdriver, you’d fight torque kickback and reposition constantly. But with the L-Handle, one steady push delivers controlled rotation—your hand remains stable, your target stays aligned, and the job gets done in half the time. Engineers report completing tasks in spaces previously deemed “tool-inaccessible,” all thanks to this elegant balance of form and physics.

This tool doesn't belong to one trade—it thrives across them. In a German auto plant, a quality inspector uses it daily to verify over 400 fasteners per shift, relying on its consistent feedback to detect micro-loosening before it becomes failure. Hundreds of feet above ground, a wind turbine technician trusts its non-slip grip and lanyard-ready handle during gusty repairs, knowing a dropped tool could be catastrophic. Meanwhile, in a quiet mold-making workshop, a master craftsman adjusts micron-level fittings with such finesse that colleagues say he "feels the thread breathe."

These aren’t isolated cases. They reflect a broader truth: when reliability becomes second nature, excellence follows.

Hold the L-Handle Line Screwdriver once, and the difference speaks for itself. The soft-touch rubberized grip conforms gently to your palm, absorbing vibrations that would otherwise travel up your forearm. The center of gravity sits perfectly between your fingers, eliminating the "nodding" effect common in poorly balanced tools. Even in cold conditions, the material retains warmth longer than bare metal, reducing numbness during prolonged use.

But the real magic hides in what you don’t notice—the absence of sharp edges, the seamless transition from handle to shaft, the subtle cushioning that dissipates shock with each turn. One user put it plainly: “I used it for six hours straight during a gearbox overhaul. At the end of the day, my hands weren’t screaming. That’s not normal.”

To prove its mettle, we subjected the L-Handle to trials few tools survive. Submerged in synthetic oil for 72 hours, then tested for grip retention—pass. Repeated impact loading simulating five years of daily use—no deformation. Exposed to -30°C temperatures followed by rapid warming—zero cracking or delamination. These aren’t hypotheticals. They mirror actual field conditions faced by maintenance crews in arctic drilling stations, offshore rigs, and high-speed production floors.

And behind every unit is a commitment: 13 inspection stages, including magnetic particle testing for internal flaws and laser verification of tip accuracy. Because when performance can’t afford compromise, neither can manufacturing.

A great tool does more than complete a task—it elevates the person using it. There’s pride in wielding something that refuses to fail, that responds precisely to intent, that feels like an extension of skill rather than a limitation. The L-Handle Line Screwdriver represents more than engineering prowess; it honors the dignity of craftsmanship. It says: Your work matters. Your effort deserves support. Your expertise demands a worthy companion.

In a world still clinging to outdated tools, choosing the L-Handle isn’t just practical—it’s a statement. A declaration that you value precision over shortcuts, endurance over convenience, and long-term performance over short-term savings.

If you're still forcing torque through a twisted wrist, fighting slippage with sweaty palms, or doubting whether your tool will last the next job—ask yourself: Is this really the best I can do? The answer might just lie in a simple shift of angle, weight, and design. Less fatigue. Sharper control. Unshakable confidence.

True performance doesn’t shout. It turns—smoothly, steadily, silently—again and again. And with the L-Handle Line Screwdriver in hand, every rotation carries the weight of certainty.