L-Handle Line Screwdriver – Industrial Grade Precision & Durability for Professionals

Engineered for strength, designed for mastery — the L-Handle Line Screwdriver stands ready where ordinary tools fail.

High above the city skyline, a senior electrician balances on a steel truss, wind tugging at his harness. Below, the hum of transformers pulses through the substation. In his gloved hand, an L-handle screwdriver bites into a stubborn terminal block. One wrong twist could mean arcing, downtime, or worse. He doesn’t flinch. Because he knows his tool won’t fail. When your livelihood hangs in the balance—literally—your tools must be more than functional. They must be trustworthy. So ask yourself: when the job turns critical, is your screwdriver built for the moment?

Precision-forged S2 alloy steel meets rugged ergonomics — every component engineered for real-world resilience.

This isn't just a screwdriver—it's a system forged from necessity. At its heart lies a cold-forged S2 alloy steel blade, heat-treated to resist deformation under repeated impact. Unlike cheaper chrome-vanadium steels, S2 maintains hardness and edge retention even after thousands of torque cycles. Whether you're breaking loose corroded fittings or tightening safety-critical joints, the tip stays true, bite after bite. The handle? Crafted from glass fiber-reinforced nylon, it resists oils, solvents, and temperatures up to 180°C. Drop it down a machinery pit? It walks away uncracked. This is material science applied where it matters most: in the hands of those who can't afford compromise.

The 90-degree L-shape isn’t merely ergonomic—it’s mechanical genius. By aligning force directly along the axis of rotation, it transforms wrist motion into pure torque. No awkward twisting, no strain on tendons. Just clean, controlled power transfer that reduces fatigue during extended use. It’s why maintenance technicians in factories, offshore rigs, and high-rise installations reach for this design when efficiency and accuracy are non-negotiable.

From factory floors to shipboard panels, professionals rely on silent performance when every turn counts.

Take Maria, an automation technician in a Midwest manufacturing plant. Her shift begins with recalibrating robotic arms bolted with recessed hex screws. Sweat drips from her brow as she works in cramped enclosures. With standard tools, slippage scars surrounding components. But the L-handle’s precisely milled tip grips without cam-out, protecting delicate sensors nearby. Or consider James, a marine electrician repairing navigation systems aboard cargo vessels. Salt-laden air eats at inferior metals, but the screwdriver’s phosphated surface resists corrosion like a seasoned sailor. And then there’s Lin, assembling aerospace molds in Shanghai, where vibration from nearby presses would numb lesser tools. Thanks to balanced mass distribution and anti-vibration geometry, her hands stay steady—even after eight hours.

These aren’t isolated anecdotes. They reflect a deeper truth: the best tools don’t announce themselves. They simply perform—quietly, consistently, day after grueling day. That’s the hallmark of professional-grade gear: silent reliability in the face of chaos.

To see the difference, imagine a stress test: eight straight hours driving M6 bolts into hardened steel plates. A typical hardware-store screwdriver shows wear within two hours—its tip begins to mushroom, then crack. The plastic handle develops hairline fractures, eventually splitting under load. Now examine the L-Handle Line Screwdriver post-test. The blade remains dimensionally stable. The knurling on the grip hasn’t smoothed. Torque accuracy holds within ±3%. There’s no debate: investing in industrial-grade tools isn’t about ego. It’s about avoiding costly rework, preventing workplace injuries, and preserving your reputation—one perfect fastening at a time.

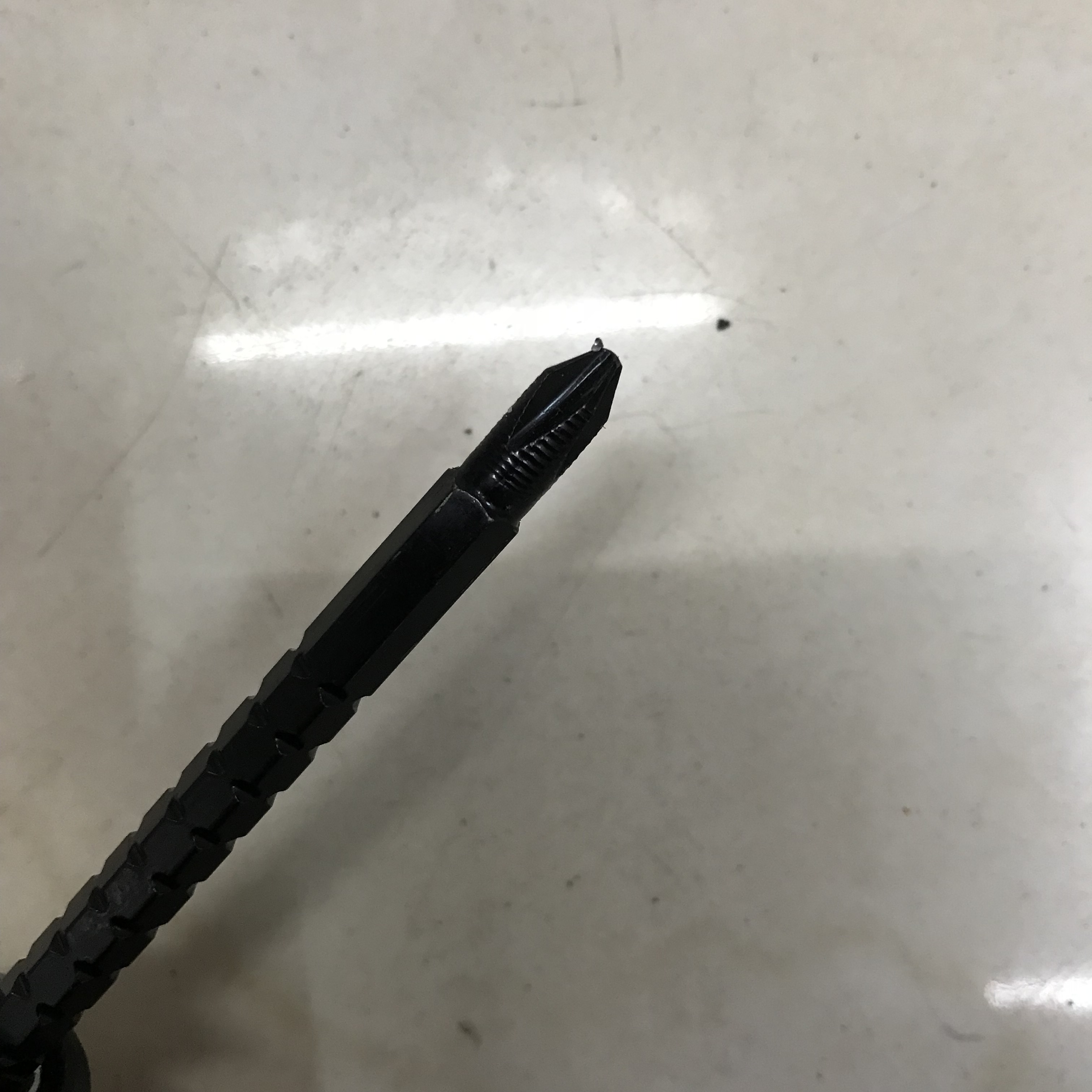

Every detail serves a purpose. The blade width matches ISO-standard slots to within 0.05mm, minimizing play and maximizing contact. The hexagonal handle features flat sides to prevent rolling, crucial when working on sloped surfaces or ladders. Even the finish—a matte black phosphating—does more than look professional. It traps lubricants, enhances grip in oily environments, and forms a sacrificial layer against rust.

In an age of disposable gadgets and planned obsolescence, choosing a tool meant to last decades feels revolutionary. Yet for true artisans, it’s instinctive. A well-made screwdriver becomes part of your identity—an extension of skill, pride, and responsibility. It says you care not just about finishing the job, but how it’s done. When you select industrial-grade equipment, you’re not buying convenience. You’re honoring craftsmanship.

If this tool could speak, it might tell stories few will ever hear: the final connection inside a wind turbine before first power generation, the life-saving calibration of a hospital MRI machine, the midnight repair keeping a production line alive. These moments go unnoticed by the world—but not by those who were there, wrench in hand, trusting their tools to deliver.

Because real professionalism isn’t found in grand gestures. It lives in the quiet confidence of turning a screw exactly once—and knowing it will hold for years to come.