The L-Handle Line Screwdriver — precision-engineered for maximum control and durability.

In the world of industrial maintenance and equipment assembly, the right tool doesn’t just make a job easier — it defines safety, efficiency, and long-term reliability. Among the countless hand tools crowding toolboxes, one stands out with quiet confidence: the L-Handle Line Screwdriver. More than just a design twist on tradition, this tool represents a thoughtful evolution in manual torque application, built specifically to meet the relentless demands of industrial professionals.

The Evolution of Precision: From Concept to Industrial Reality

The story of the L-Handle Line Screwdriver begins with a simple question: how can we reduce strain while increasing control during repetitive screw-driving tasks? Traditional straight-handle screwdrivers often force users into awkward wrist angles, especially in tight or overhead spaces. Engineers and designers responded by reimagining leverage and ergonomics — leading to the L-shaped handle, which aligns the user’s arm and wrist in a natural position, allowing force to be applied more efficiently through the shoulder and forearm.

This shift wasn’t merely aesthetic. It was born from real-world challenges faced daily in factories, power plants, and mechanical workshops. The L-handle transforms rotational effort into a smoother, more powerful motion, reducing fatigue and improving accuracy — a critical advantage when working under time pressure or in hard-to-reach areas.

Real Challenges in Industrial Environments

Industrial settings push tools to their limits. Technicians routinely face cramped enclosures, stubborn fasteners, and extended shifts that test both endurance and equipment resilience. Standard screwdrivers often fail on multiple fronts: slipping tips damage screws, weak shafts bend under pressure, and poorly designed handles lead to hand cramps and repetitive strain injuries.

Moreover, inconsistent torque delivery can result in under-tightened connections — a hidden risk in electrical systems or structural assemblies — or over-torqued screws that strip threads and compromise integrity. In such high-stakes environments, even minor inefficiencies compound into major delays, safety hazards, and costly rework.

An industrial technician applies precise torque using an L-Handle Line Screwdriver in a confined space.

The Engineering Edge: What Sets the L-Handle Apart?

At first glance, the L-Handle Line Screwdriver may appear deceptively simple. But beneath its sleek profile lies a suite of engineered advantages. Its ergonomic handle promotes a neutral wrist posture, minimizing stress during prolonged use. This isn't just comfort — it's injury prevention. Studies show that maintaining a straight wrist alignment reduces the risk of carpal tunnel syndrome and other musculoskeletal disorders common among technicians.

The true strength, however, lies in its ability to deliver superior torque. By leveraging the entire arm rather than relying solely on wrist rotation, users achieve greater turning power with less effort. The rigid shaft, forged from hardened chrome-vanadium steel, resists twisting and deformation, ensuring consistent performance across thousands of cycles.

Each tip is precision-machined to match industry-standard screw heads — Phillips, slotted, or Pozidriv — minimizing cam-out and protecting both fastener and tool. Combined with anti-slip knurling on the handle, the L-Handle ensures confident grip even in oily or wet conditions.

Voices from the Field: Trusted by Professionals Who Depend on It

"I’ve used standard drivers for years, but once I switched to the L-Handle, there was no going back," says Marcus Tran, a senior maintenance engineer at a Midwest manufacturing plant. "It gives me better reach into control panels and cuts my assembly time nearly in half."

Electrical installers working on switchgear and distribution boards report similar benefits. One utility technician noted how the tool’s compact profile allowed access behind live panels without disassembly, significantly reducing downtime. Meanwhile, field service teams servicing heavy machinery praise its durability — surviving drops, exposure to grime, and continuous use with minimal wear.

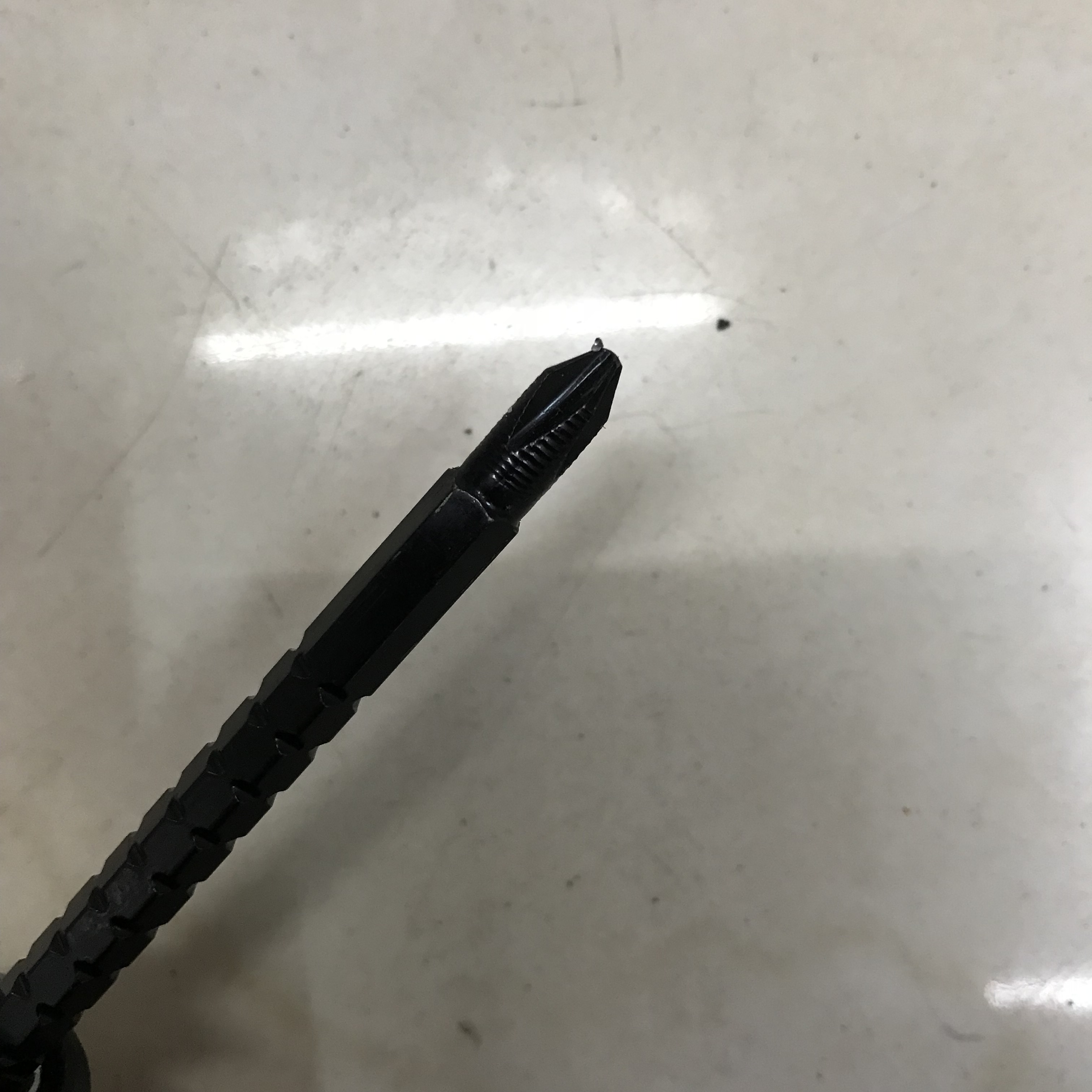

Precision tip and reinforced shaft ensure reliable engagement and long-term performance.

Driving Efficiency, Reducing Costs

Beyond individual comfort, the L-Handle Line Screwdriver delivers measurable operational improvements. Teams report faster task completion, fewer tool changes, and reduced error rates due to improved control. Because the tool lasts longer and requires less frequent replacement, companies see a direct reduction in procurement and downtime costs.

Its design also supports sustainable practices. Built to endure, it reduces waste associated with disposable or short-lived tools. For organizations focused on lean operations and environmental responsibility, this longevity is a compelling advantage.

Choosing the Right Tool for Demanding Jobs

Not all L-handle screwdrivers are created equal. True industrial-grade models feature fully forged construction, heat-treated shafts, and handles made from impact-resistant materials. Look for certifications indicating compliance with international standards like ISO 2380 or DIN 5264. Reputable brands invest in rigorous testing to validate performance under extreme loads.

Depending on your application — whether it’s delicate electronics assembly or heavy-duty mechanical repair — consider variations in tip size, shaft length, and handle finish. Some models include magnetic tips or quick-release mechanisms for added versatility.

The Future of Industrial Hand Tools

As industries embrace automation and smart diagnostics, the role of manual tools is evolving — not disappearing. The future lies in intelligent integration: imagine an L-Handle screwdriver with embedded torque sensors feeding data to a maintenance log, or handles molded from recycled aerospace composites. The principles of ergonomics, durability, and precision will remain central, and the L-Handle design is poised to lead this next generation.

In an era where every second counts and worker well-being is paramount, the L-Handle Line Screwdriver proves that sometimes, the most powerful innovations come not from digital disruption, but from rethinking the fundamentals of human-centered design.