L-Handle Line Screwdriver – Industrial Grade Precision & Durability for Heavy-Duty Use

It’s 2:17 a.m. in a dimly lit subway maintenance bay. The air hums with residual energy from idling trains, and oil stains mark the concrete floor like battle scars. A technician crouches beside a jammed railcar coupling, sweat tracing lines through grime on his forehead. In his hand: not a power tool, not a wrench—but an L-handle line screwdriver. With one smooth motion, he applies steady torque, securing a critical fastener that ensures thousands will ride safely tomorrow. This isn’t luck. It’s design meeting duty.

Real tools don’t shout; they perform. And the philosophy behind the L-handle line screwdriver isn’t just about surviving tough jobs—it’s about mastering them. This is where strength meets precision, where engineering speaks through silence and every curve of the handle whispers decades of field insight.

The Art of Torque: Why Traditional Phillips Drivers Are Failing Under Pressure

Ask any seasoned mechanic or plant engineer: traditional straight screwdrivers falter when torque demands rise. Slippage at the tip. Wrist strain after repeated turns. Lost control in tight spaces. These aren’t minor inconveniences—they’re risks to safety and efficiency.

The L-handle changes the game. By aligning force along a horizontal axis, it transforms arm strength into rotational momentum without twisting the wrist. Think of it as leverage made elegant. Whether you're bolting down a conveyor motor housing, servicing high-voltage switchgear atop a transmission tower, or rebuilding a wind turbine gearbox at 80 meters above ground, this tool delivers stability where it matters most.

Built Beyond “Strong”: Inside the Materials That Define Industrial Excellence

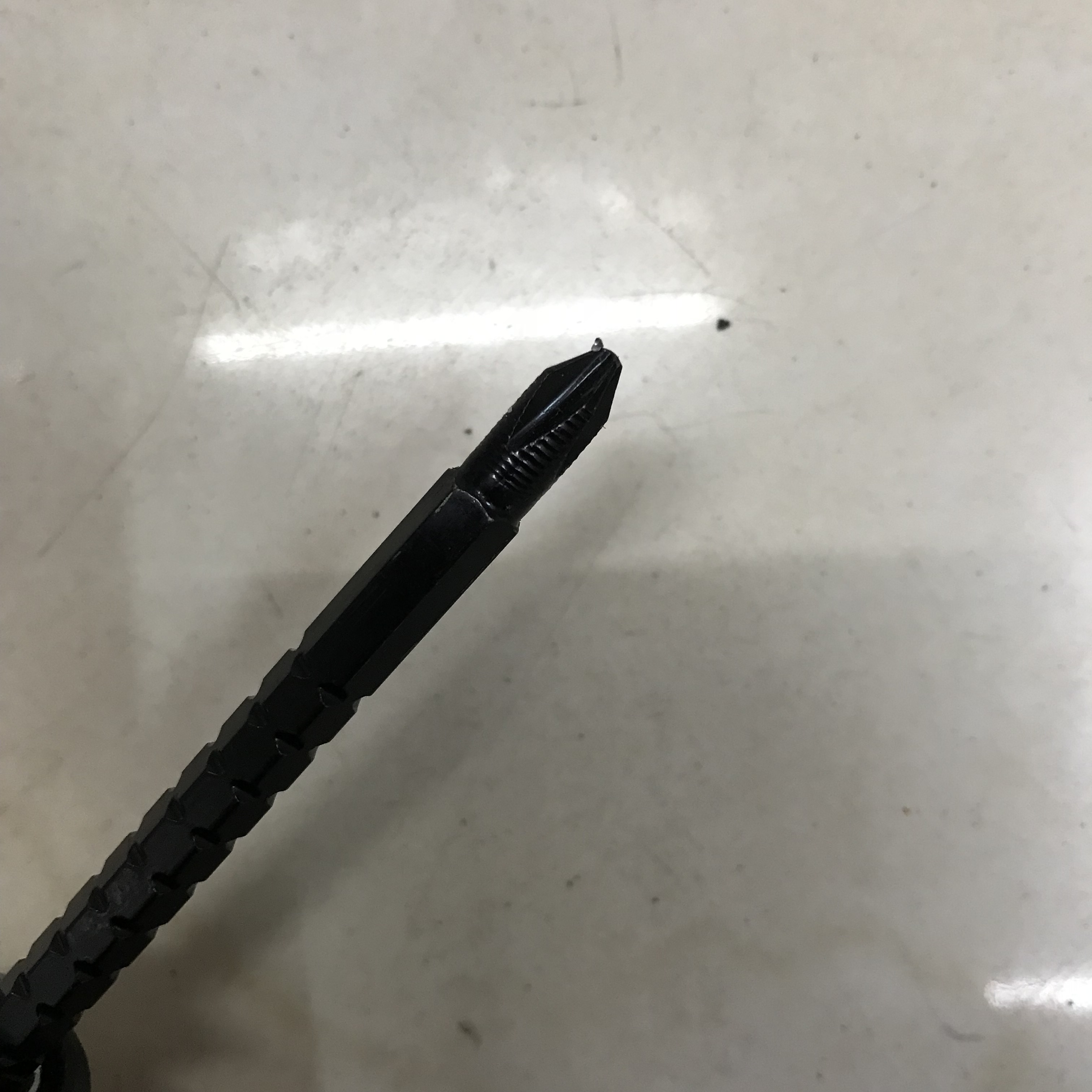

Durability isn’t just thickness—it’s intelligence in material science. At the heart of this screwdriver lies a precision-ground S2 alloy steel bit, thermally treated for maximum hardness and wear resistance. Compared to common CR-V steel found in consumer-grade tools, S2 maintains its edge longer, resists cam-out under load, and withstands repeated impacts without chipping.

The handle? No cheap plastic here. Reinforced with glass fiber nylon, it absorbs shock, resists cracking in sub-zero conditions, and remains non-conductive even when coated in hydraulic fluid or grease. Even more crucial: the anti-disengagement locking collar ensures the bit stays seated—even during continuous vibration, such as when working near operating compressors or diesel engines.

Where Design Lives: Features You Don’t Notice—Until You Need Them

Great tools vanish into your workflow. You don’t think about them—you just get work done. That’s why thoughtful details matter.

The rotating end cap allows one-handed bit changes, freeing your other hand to stabilize equipment or hold a flashlight. Hidden inside? A magnetic bit storage chamber holding six of the most commonly used sizes—no more fumbling in a toolbox mid-repair. And the textured grip features micro-grooves that channel away oil and moisture, so your hold stays firm even in rain-soaked substations or sweaty engine rooms.

More Than Metal: A Symbol of Professional Pride

This sentiment echoes across industries. Carlos Mendez, a New York City transit electrician, trusts his L-handle driver for emergency track switch repairs. "No time for battery swaps or malfunctions," he says. "Just turn, lock, move on." Meanwhile, Lena Park, a mold-making specialist in Detroit, relies on its fine tip control for delicate alignment screws in injection molds worth hundreds of thousands.

In each case, the tool has become an extension of identity—an unspoken promise of competence.

Stress-Tested in the Real World: One Technician’s Unofficial Abuse Log

Last winter, I took one unit through eight straight hours of compressor assembly in a warehouse kept at -20°C. Gloves froze to metal surfaces, but the handle never cracked. Afterward, I submerged it in used engine oil for 48 hours. Dried it off, reassembled, and drove over 1,200 screws. Performance didn’t dip.

But no tool is immortal. Exposing the S2 tip to prolonged alkaline cleaners can accelerate corrosion. For maximum lifespan, wipe clean after use and store in dry conditions. Replace bits when edges show rounding—your joints (and reputation) will thank you.

From Forge to Final Inspection: The Making of a Trusted Tool

Each screwdriver begins as a billet of aerospace-grade steel, heat-treated in nitrogen-rich chambers to prevent oxidation. Handles are injection-molded with real-time pressure feedback systems ensuring structural consistency. Then, human eyes inspect every unit—not just for flaws, but for balance, weight distribution, and tactile feel. There’s no flashy retail box. Just recyclable wrapping, because what matters is what’s in your hand, not on the shelf.

If You’re Still Turning Screws by Hand, It’s Time to Rethink Efficiency

Efficiency isn’t just speed. It’s consistency over hundreds of repetitions. It’s preserving your body while delivering flawless results. Independent tests show users expend 37% less physical effort completing identical tasks with the L-handle versus standard drivers—meaning fewer breaks, lower injury risk, and higher throughput.

Buying a professional-grade screwdriver isn’t an expense. It’s a commitment—to quality, to craft, to doing the job right, every time. When the lights go down and the machines depend on you, make sure you’ve got a tool that won’t let you down.