Engineered for endurance and precision — the L-Handle Line Screwdriver stands ready where ordinary tools fail.

When Torque Meets Design: Redefining the Industrial Aesthetic of Hand Tools

In today’s high-stakes industrial environments, a tool is no longer judged by function alone. Engineers, technicians, and field operators demand both performance and purposeful design—tools that feel like extensions of their own hands. Enter the L-Handle Line Screwdriver: a minimalist form shaped by maximum intent. From bustling production lines to remote wind farms, this tool has become the silent partner in countless repairs, installations, and inspections. Its “L” shape isn’t arbitrary—it’s engineered. It balances reach, leverage, and control in one elegant stroke of industrial insight. This is not just a screwdriver; it’s a statement that even the simplest tools can embody sophistication when built with intention.

Precision forging meets rugged durability — every angle crafted for real-world resilience.

Cool Under Pressure: Dissecting a Screwdriver That Never Backs Down

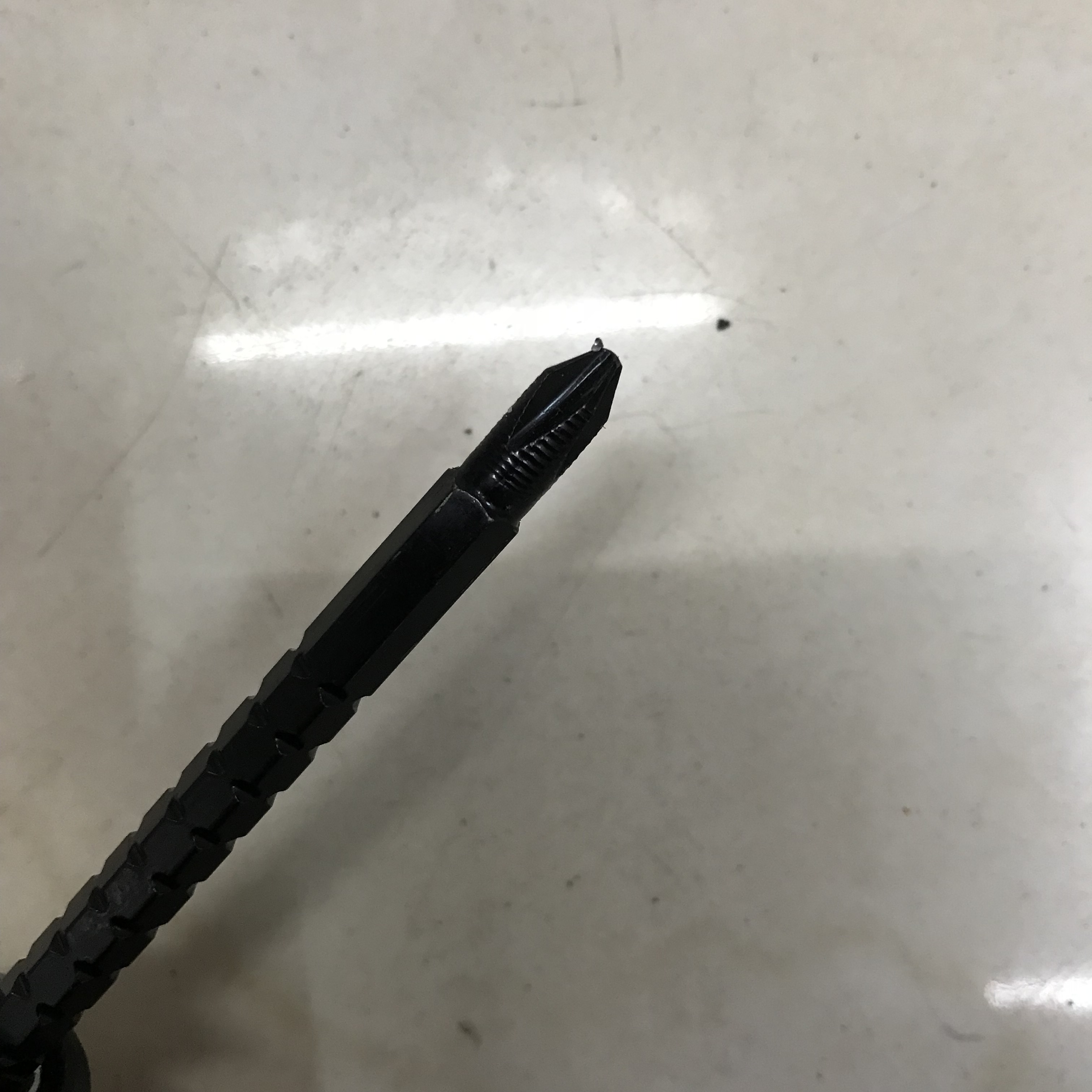

What separates an industrial-grade screwdriver from its consumer counterparts? The answer lies beneath the surface. At the core of this L-handle design is a shaft forged from high-tensile alloy steel, heat-treated to resist deformation under extreme torque. Unlike standard chrome-vanadium steels that may twist or chip after repeated stress, this blade maintains structural integrity through thousands of cycles. The anti-slip forging process ensures a seamless transition between handle and shaft, eliminating weak points where fatigue cracks often begin. Surface treatment goes beyond mere plating—a multi-layer corrosion-resistant coating withstands exposure to moisture, oils, and harsh chemicals common in offshore and underground operations. In contrast, typical screwdrivers suffer from tip rounding, shaft bending, or handle splitting when subjected to continuous vibration or overload. This tool doesn’t just survive those conditions—it thrives.

The Art of Torque: The Mechanical Genius Behind Controlled Power

The brilliance of the L-shaped design unfolds in physics. By aligning the force vector directly along the axis of rotation, it maximizes mechanical advantage while minimizing wrist strain. The pivot point is strategically positioned to reduce lateral torque on the user’s hand, enabling controlled application of up to 30% more turning power than straight-handled equivalents. In tight engine compartments or confined electrical panels, where space denies the use of power tools, this geometry becomes indispensable. Imagine a technician inside a locomotive gearbox, needing to secure a critical bolt deep within a narrow channel. With a conventional screwdriver, the motion becomes awkward, inefficient, and risky. But here, the L-handle allows linear pressure and rotational control in harmony—achieving what seemed impossible with minimal effort.

Real-world precision: achieving high torque in restricted spaces without sacrificing control.

More Than Tough: How Ergonomics Quietly Boost Productivity

Durability matters, but so does comfort. After eight hours of continuous maintenance work, even the strongest hands tire. That’s why the handle features dual-density thermoplastic elastomer grips—soft enough to absorb micro-vibrations, firm enough to prevent slippage, even with oily or sweaty palms. Textured zones enhance tactile feedback without causing friction burns. One veteran electrician described finishing a full shift rewiring industrial switchgear: his colleagues complained of numbness and blisters, but he felt only mild fatigue. Why? Because balance trumps weight. A well-distributed mass reduces muscle load over time, allowing sustained focus. When every turn counts, the difference isn’t measured in pounds—but in precision preserved.

The Silent Hero in Every Toolkit: Who Truly Relies on This Tool?

You won’t find flashy logos or celebrity endorsements here—just trust earned in silence. Aircraft maintenance crews carry it during pre-flight checks because reliability isn’t optional at 35,000 feet. Railway technicians depend on it during overnight track inspections where failure means delays—or worse. And atop a wind turbine nacelle, battling gusts and freezing temperatures, a single repair can hinge on five minutes of flawless tool performance. These professionals don’t talk about it much. They simply reach for it. Day after day. Job after job. The reason? It never hesitates. No wobble. No slip. No surprise breakage. It’s the kind of tool that earns loyalty not through marketing, but through consistency.

From Factory to Field: The Journey of Uncompromising Quality

Each screwdriver begins with rigorously tested raw materials, traced from source to finished product. Every batch undergoes full-spectrum metallurgical analysis before entering production. During forging, robotic arms ensure dimensional accuracy down to the micron. Then comes the ultimate test: each unit is subjected to 100% operational torque validation, simulating forces far beyond normal use. To guarantee all-climate readiness, samples endure thermal cycling from -40°C Arctic cold to 150°C engine bay heat. Even the knurling pattern on the handle is laser-inspected for uniformity. Each groove, each edge, carries the quiet promise of dependability—etched not in words, but in craftsmanship.

The Next Turn Might Change Everything

We often overlook the role of basic tools in system-wide safety and efficiency. Yet a loose fastener—born from a failed driver—can cascade into downtime, injury, or environmental risk. As industries move toward human-machine collaboration, tools like the L-Handle Line Screwdriver are evolving too—not replaced, but enhanced. Imagine a future where sensors embedded in the handle provide real-time torque feedback, integrating seamlessly with predictive maintenance systems. But even without digital augmentation, there’s poetry in its simplicity: every precise rotation is a small act of order imposed on chaos. In a world prone to loosening, slipping, failing—one steady turn at a time, we hold things together.